Guangdong Dahe Aluminum Co., Ltd.

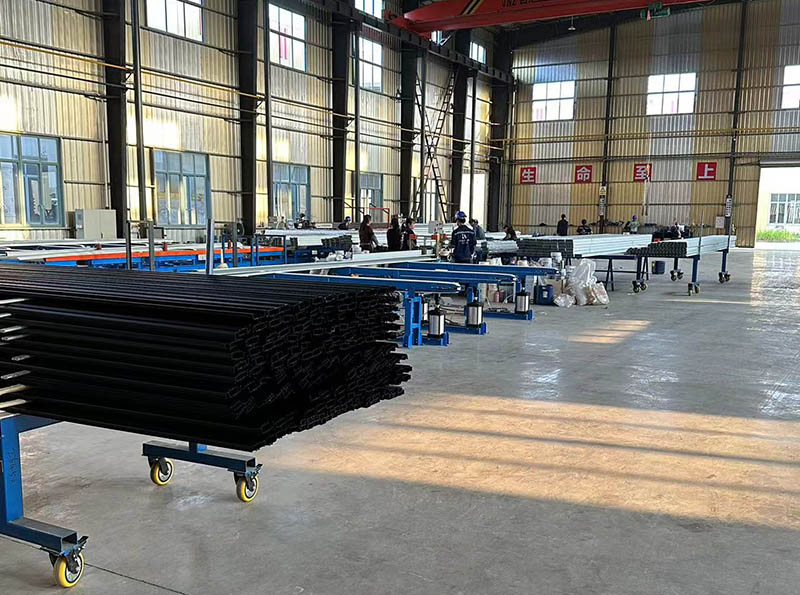

Located in Beishui Avenue,Beishui Development Zone ,Yong an,Zhaoqing.The company covers an area of more than 400 acres and the whole lines will produce about 50, 000 tons of aluminium profiles per year, with an output value of about 1 billion yuan, and total more than 500 employees.

Committed to improving the quality and service level of doors and windows in China

Main building products: curtain wall series and door and window series, sliding window, casement window, sliding door, swing door, fixed door, energy-saving heat insulation (broken bridge) door and window series;

industrial products: bicycle aluminum alloy body bracket, mobile phone board, Various electronic product radiators, photovoltaic solar frames, TV frames, etc.;

surface treatments: anodizing, electrophoretic coating, powder coating and fluorocarbon spraying, as well as imitation stone, imitation wood grain, polishing, etc.

Why US ?

Guangdong DaHe Aluminium Co., Ltd. is a large-scale enterprise specializing in the production of aluminium profiles. The company has introduced advanced aluminium profile production equipment and automatic production lines from Taiwan, Japan, South Korea, Germany, the United States, Switzerland and other countries. In strict accordance with the national GB5237-2008 and European, American, New Zealand and other national standard organizations produce.

Our Plan

The company plans to invest about 100 million yuan in equipment. The extrusion workshop plans to assemble 15 production lines with extrusion capacity ranging from 660 tons to 2,500 tons. The oxidation workshop will introduce a Japanese HAN electrophoresis production line with the current industry-leading advanced digital control system, and a spraying workshop. Equipped with 3 professional powder and fluorocarbon spraying production lines from WAGNER, Germany.

In order to meet the needs of national energy-saving buildings, there are 8 production lines of pierced-type heat-insulating aluminum alloy building profiles. 4 aluminum alloy energy-saving aging furnaces. There are 2 aluminum bar energy-saving melting and casting furnaces, CNC machining centers and other equipment.

Our Goal

DaHe Aluminum adopts the ERP system. The goal is to be market-oriented and customer-oriented, to optimize the allocation of internal and external resources, to realize the organic integration of information flow, logistics, capital flow, business flow and value flow, and to improve the competitiveness of the enterprise. At the same time, planning and control are the main line, with network and information technology as the platform, integrating functions such as customer, market, sales, planning, procurement, production, finance, quality, service, information integration and business process reengineering (BR) to strengthen supply.

core technology

Billet Casting

DaHe Aluminum has the most advanced melting and casting production equipment in the United States,which and produce aluminum rods with different alloy compositions.Products include 6series of extruded aluminum alloy rods.

- With electromagnetic stirring melting furnace and tilting static furnace

- Hydraulic casting machine

- Aluminum melt online purification device and photoelectric spectrometer have international advanced Advanced production and online testing equipment

- Multiple horizontal and chamber type homogenizing furnaces

Extrusion

It has several first-class and advanced extrusion production lines ranging from 600 tons to 2,500 tons, and has the world’s top extrusion technology equipment and excellent supporting equipment such as aluminum bar power frequency gradient heating furnace, online quenching and cooling, annealing furnace, and vertical quenching furnace.

Surface Treatment

Japan Hani system aluminum electrophoresIs production line

- (It can produce various plates of 0.03mm -4mm thickness: 0.5mm-1.65m width)

- Fully automatic aluminum tri-acid oxidation production line

- German automatic powder coating production line

- German automatic fluorocarbon spraying production line